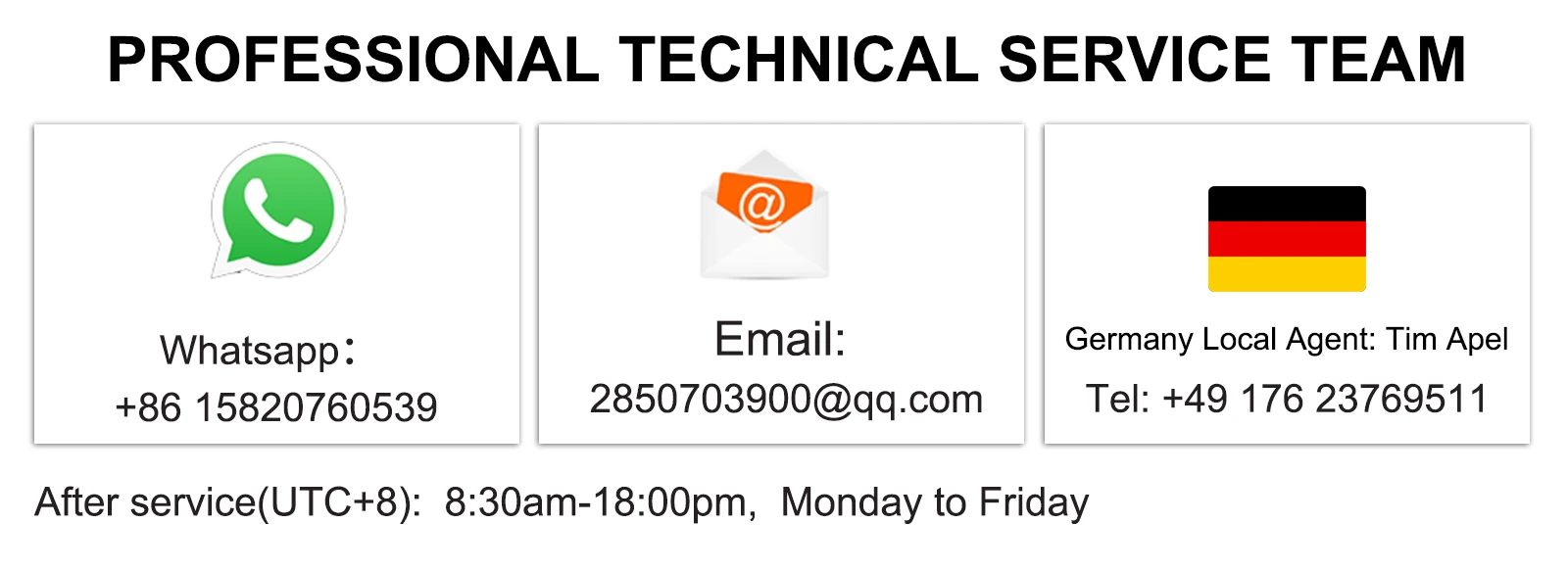

Raycus 3000W 4 in1 Fiber Laser Welding/Cleaning Welder Machine& 2 Channel Feeder machine

Raycus 3000W 4 in1 Fiber Laser Welding/Cleaning Welder Machine& 2 Channel Feeder machine

Verfügbarkeit für Abholungen konnte nicht geladen werden

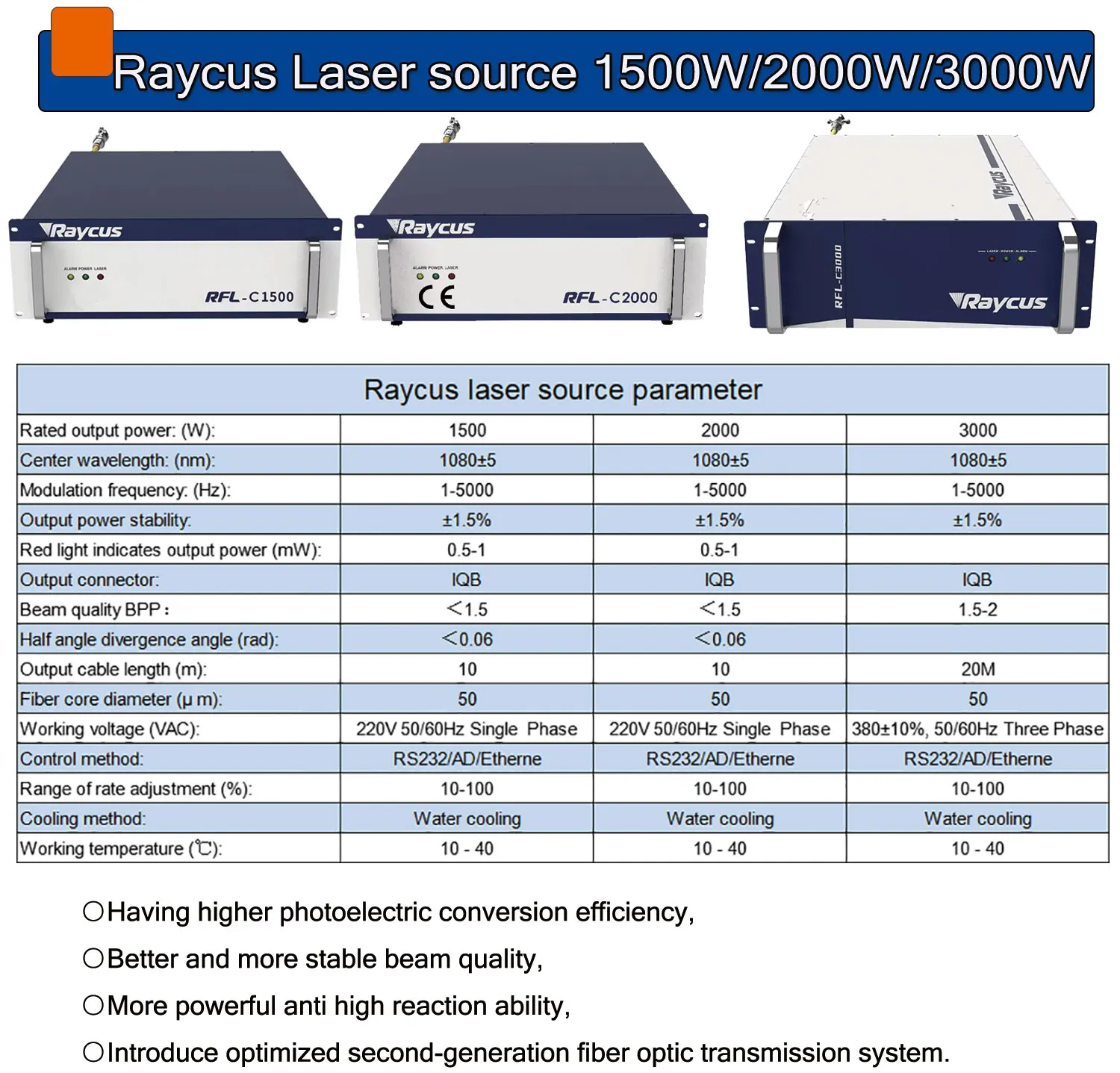

SPECIFICATIONS

Brand Name: cnczone

Hign-concerned Chemical: None

Origin: Mainland China

Main Advantages:

1.High cleanliness.

2.Precise positioning cleaning.

3.Non-contact cleaning, protecting brittleness material surface.

4.Effective removal of micron pollution particles.

5.Environment friendly type, No consumables.

Laser welding

1) the weld is smooth and beautiful, the weld workpiece has no deformation, the weld is firm, and no

Subsequent grinding process is required, saving time and cost.

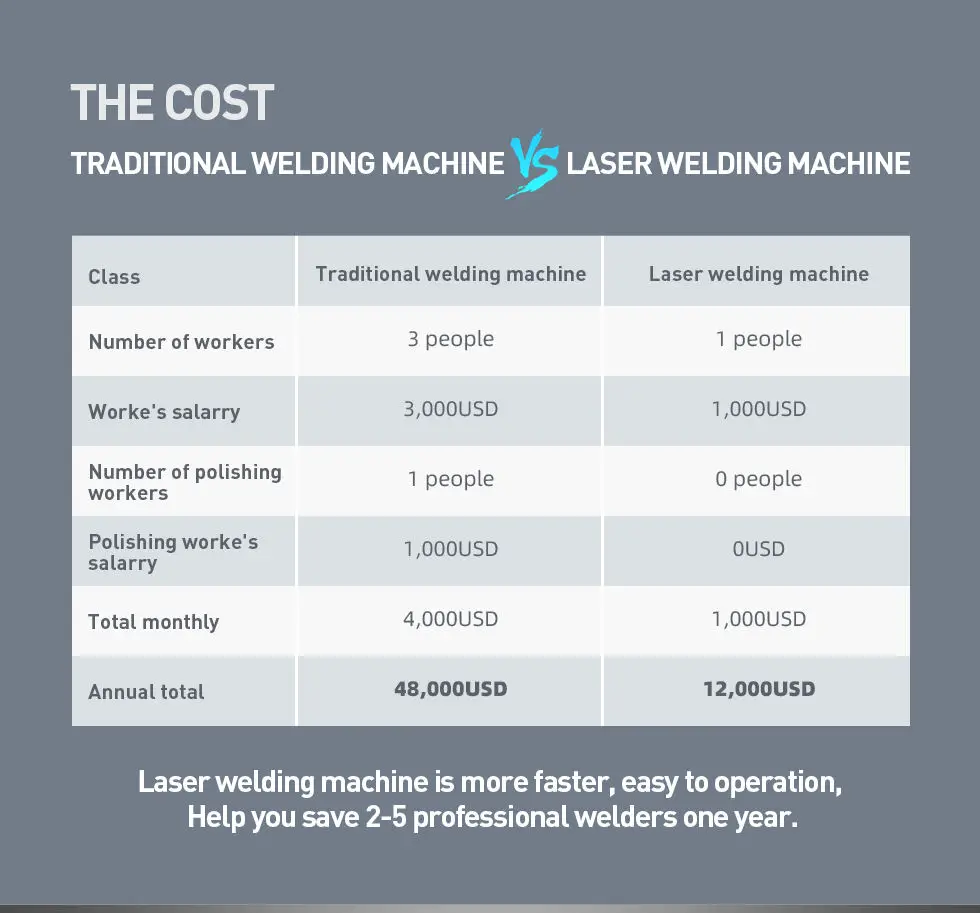

Fast welding speed, 2~10 times faster than traditional welding.

2) Easy operating do not require any training

Welding seam beautiful smooth and beautiful, don't need polish, save your time

No deformation or welding scar, welding the workpiece firmly.

3) easy maintenance

Laser welding has less consumption and long service life. Safer, more environmentally friendly.

4) Wildly used in kitchen and bathroom cabinet, stair lift, shelf, oven, stainless steel door and window

Guardrail, distribution box, stainless steel home.

Laser cleaning

1) Laser Rust Removal: Laser light can easily remove rust, after removal, the surface is restored to a bright metallic color or restore the original base color.

2) Laser Oil Removal: Metal surface oil cleaning (can remove oxide layer at the same time)

3) Laser Color Removal: removes various colors including Auto Duco on various surfaces and cars

4) stripping plating (galvanized layer, aluminized layer, protective plating, etc.)

5) Removal of aluminum alloy, titanium alloy, copper alloy oxide layer

6) Pre-Weld Pretreatments: After laser cleaning pretreats the aluminum alloy, the welding porosity defects are effectively suppressed

7) Post-weld cleaning: Non-Contact NDT removal of post-weld oxide layer and slag residue

8) Aluminum alloy pulsed laser remove dirt and oxide film before welding

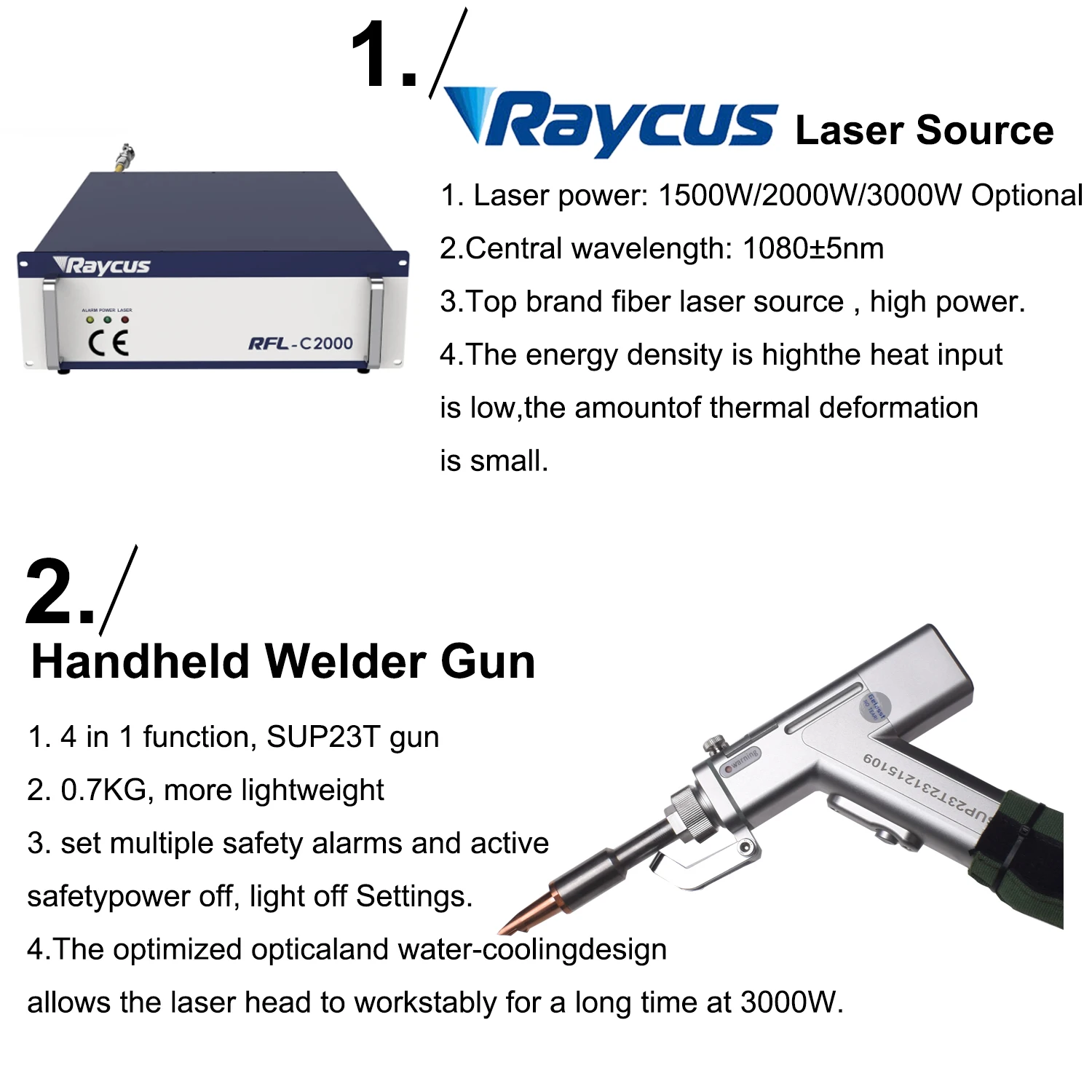

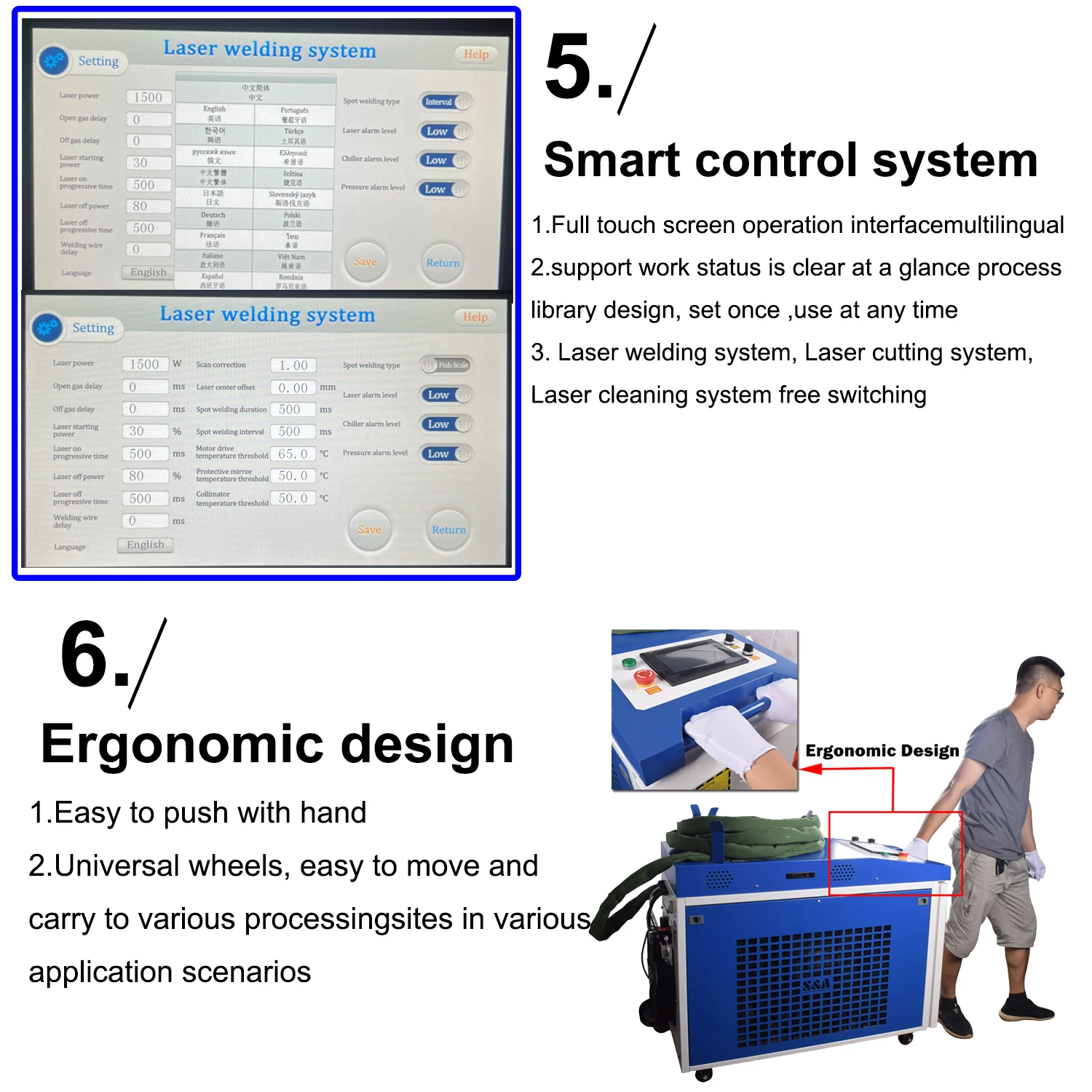

4 In 1 Welder Laser Soldering Machine Combo Laser Metal Cleaning Main Features

1. Three working modes, welding + cutting + cleaning. Simple switching, only need to replace the copper nozzle,

switch the system

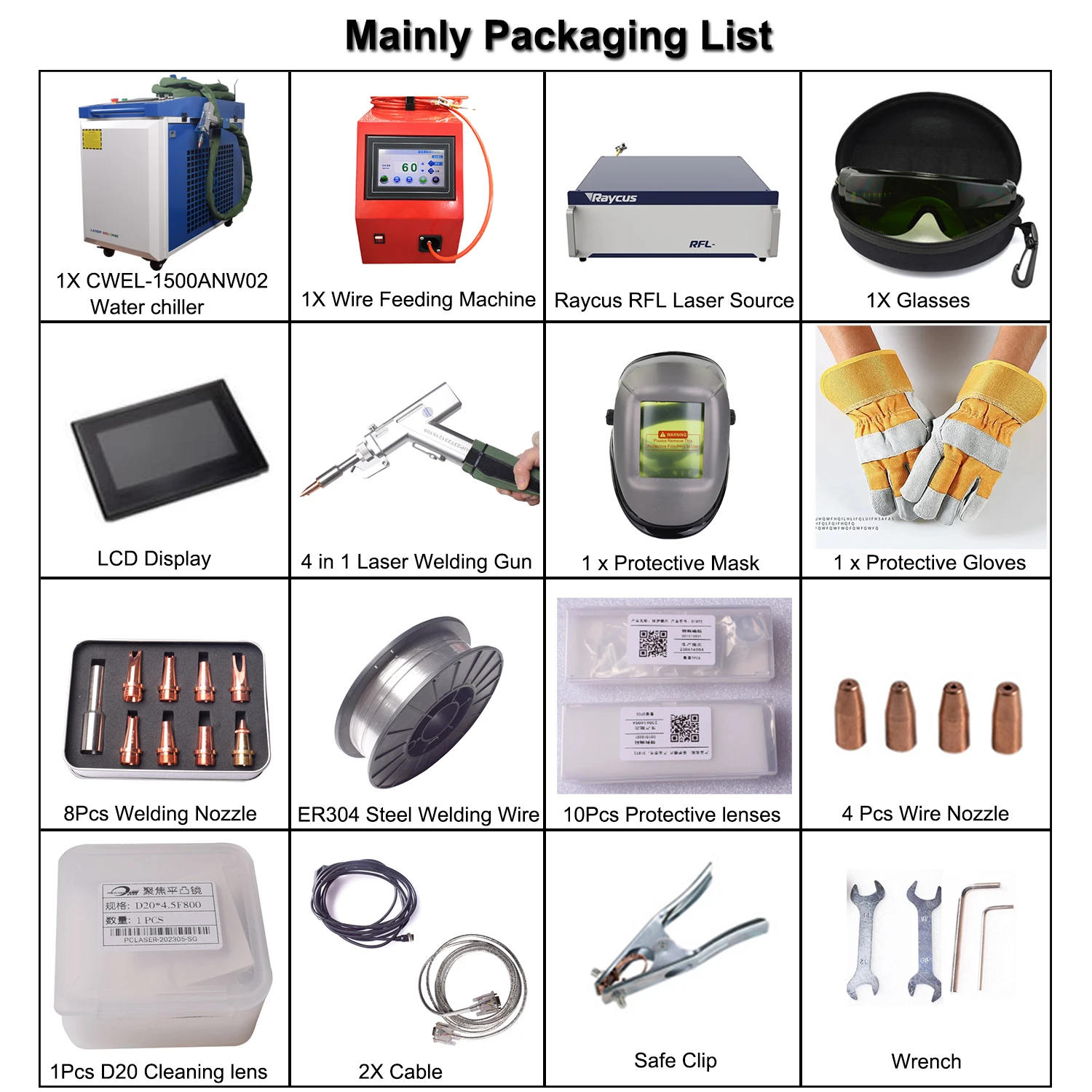

2. About fiber cable length

Standard length is 10m, if you have other needs, we support shortening or lengthening.

3. Auxiliary gas: nitrogen or argon

If the welding surface effect is required to be white and bright, nitrogen or argon is required

If there is no requirement for the welding surface, add compressed air freeze Dryer, air is OK.

4. About wire feeder

It's the machine standard configuration, we will send to you together with the whole machine.

5. Machine warranty: 3 years for whole machine, 2 years for laser generator.

Laser Welding

1) The weld seam is smooth and beautiful,The welding workpiece has no deformation, the welding is firm, and no

subsequent grinding process is required, which saves time and cost.

Fast welding speed, 2~10 times faster than traditional welding.

2) Easy operating need no training

Welding seam beautiful smooth and beautiful, don’t need polish, save your time

No deformation or welding scar, firm welding of the workpiece.

3) Easy Maintenance

Laser welding has less consumables and long service life. Safer, more environmentally friendly.

4) Wildly used in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window

guardrail, distribution box, stainless steel home.

Laser cleaning

1) Laser Rust Removal: Laser light can easily remove rust, after removal, the surface is restored to a bright metallic color or restoration of the original base color.

2) Laser Oil Removal: Metal surface oil cleaning (can remove oxide film at the same time)

3) Laser Paint Removal: removes various paints including auto Duco on various substrates and automobiles

4) Stripping coating (galvanized layer, aluminized layer, protective coating, etc.)

5) Removal of aluminum alloy, titanium alloy, copper alloy oxide film

6) Pre-Weld Pretreatments: After laser cleaning pretreats the aluminum alloy, the welding porosity defects are effectively suppressed

7) Cleaning after welding: Non-Contact NDT removal of post-weld oxide film and slag residue

8) Aluminium alloy pulsed lasers remove dirt and oxide film before welding

Share